Wear protection

For extended service life

Protect your system components from wear and avoid unplanned production downtime. During the transport and processing of bulk and piece goods, wear occurs on unprotected components. Especially abrasive wear significantly reduces the service life. Rely on our solutions for long-term plant efficiency.

CHEMONIT

Highest chemical resistance

Discover the outstanding chemical resistance of CHEMONIT hard rubber linings. They provide excellent protection against mineral acids, bases, organic solvents, and water. With a variety of bonding systems and flexible vulcanization options, they perfectly adapt to your requirements. Our hard rubber linings are approved by the DIBt in accordance with WHG §19 l and are ideal for the safe storage of water-endangering substances.

REMACLAVE 60 ISO/803

Reliable autoclave vulcanization

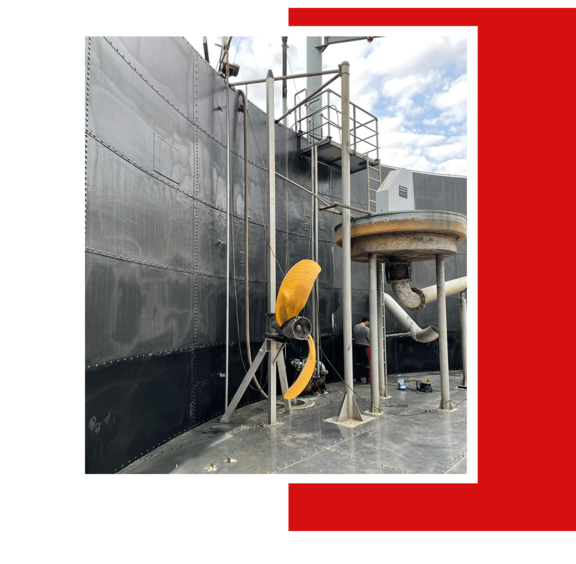

REMACLAVE 60 ISO/803 - The leading rubber lining system for shipbuilding and maritime applications. Specially designed to withstand the demanding conditions of oil-contaminated and chlorinated seawater, REMACLAVE 60 ISO/803 is the preferred choice for seawater-carrying pipelines.

INDUSTRIAL CLIMBERS

According to FISAT

Save costs on rubber lining inspections! Our specially trained FISAT industrial climbers are experienced vulcanizers as well. They enable thorough inspections of your system without the need for expensive scaffolding. In most cases, repair work can be carried out directly on the rope, eliminating the need for full scaffolding.

COROFLAKE

PUTTY COATINGS

Our putty coatings based on polyester and vinyl ester resins, reinforced with micro-thin C-glass flakes, offer outstanding performance and versatility. These COROFLAKE putty coatings can be used for almost all media and withstand wet loads of up to 90°C. Rely on the quality and durability of our COROFLAKE putty coatings for top-notch surface technology.

Stahlwasserbau

SPRAY COATINGS

Spray or roll-on techniques combine the advantages of putty coatings with the user-friendliness of spray paints.

These systems are based on high-quality vinyl ester, epoxy, and epoxy novolac resins, reinforced with C-glass flakes, mica, or graphite. COROFLAKE spray coatings provide long-term and cost-effective protection for your facilities with an impressive service life. They can withstand temperatures of up to 230°C under dry loads.

High-quality glass fiber-reinforced coatings - corrosion resistance and impact toughness

Our glass fiber-reinforced coatings with a thickness of approximately 3 mm rely on polyester, vinyl ester, epoxy, and epoxy novolac resins. These coatings are characterized by exceptional corrosion resistance, excellent impact toughness, and high abrasion resistance. They are ideally suited for applications with wet loads at temperatures of up to 70°C.

TOPLINE

OPTIMUM RESISTANCE

By using the same resins as in the TOPLINE series, the highest possible chemical resistance is achieved due to the high resin content. Cracks in concrete up to a width of 0.2 mm can be bridged. With the use of glass mats and flexible resin, this coating withstands operating temperatures of 80°C and can be cleaned with steam jet equipment.

COROPUR polyurethane coatings for atmospheric corrosion protection.

Effective protection for steel components: COROPUR offers the perfect combination of high surface hardness and high elasticity. These one-component coating systems can be easily applied by brush, roller, or spray, and are characterized by their high moisture tolerance.

Highly reactive 2-component spray system based on polyurea. Suitable for steel, concrete, plastics, and more. Resistant to moisture, low temperatures, and environmental conditions. Hardness of approximately 95 Shore A. Protection against corrosion, adhesion, and wear. Adjustable layer thicknesses from 1.5 mm to 25 mm+.

Contact Person

Martin Ahrens

Division Management Corrosion Protection

Tel. +49 (0) 4526 9829

E-Mail ahrens@~@mahnke.de