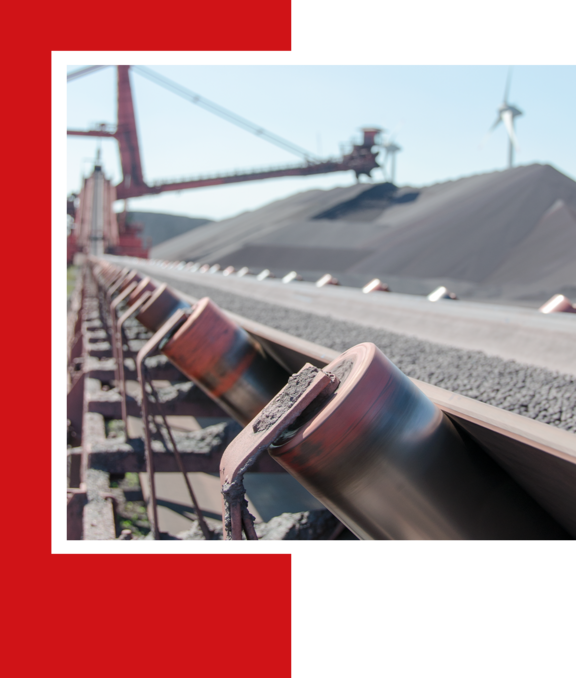

Over 40 years of customer service experience shape our conveyor technology. We have demonstrated our expertise in international projects. Our strength lies in our highly qualified team of vulcanizers and locksmiths. In addition to specialized equipment, we have an extensive range of machinery, including Unimogs and winding trolleys, as well as hot presses with a belt width of up to 3,000 mm.

Feel free to contact us to explore the diverse possibilities.

Our range of services

Thanks to long-standing partnerships with leading manufacturers in the industry, we can offer you a comprehensive range of services, from delivery to complete service. With our hot presses capable of joining belts up to 3,000 mm in width, we guarantee an optimal connection for your requirements.

SERVICE ON SHIPS

SPECIALIZED and active worldwide

Conveyor belts are not only used on solid ground but also at sea. Self-unloaders are cargo ships equipped with their own conveyor technology and capable of efficiently unloading their cargo themselves. Peter Mahnke GmbH has specialized in this segment for several years and operates worldwide.

CONFECTIONING

OUR EXTENSIVE RANGE

Our range includes not only a wide selection of standardized conveyor belts but also customized solutions tailored specifically to your system and requirements. In our own workshop, we can individually customize belts, including the integration of cleats, corrugated edges, or additional wear protection. Thanks to our extensive inventory of belt bodies and materials such as corrugated edges, we can also respond promptly to orders for customized belts.

OUR DELIVERY RANGE

To ensure a quick response time, we maintain our own stock of support and sub-belt rollers and work closely with our suppliers to deliver custom sizes at short notice. Our service goes beyond mere delivery and includes on-site inspection, evaluation, and replacement of idler rollers. We offer rollers for almost all application areas. Our delivery range includes:

OUR SERVICE FOR DRUMS AND IDLER ROLLERS

For gentle transfer of the conveyor belt, we offer not only standard products but also customized impact sections. Our service covers the entire process from measurement to the installation of impact stations. This ensures that your system is optimally tailored to meet individual requirements.

BELT ALIGNMENT

FOR OPTIMAL TRACKING

Proper alignment of the conveyor belt is crucial for the long life of conveyor systems. Belt misalignment can lead to unwanted contamination of the system and wear on supporting components. Thanks to our partnerships with renowned manufacturers, we can offer you tailored solutions for belt misalignment issues. This ensures that your system operates optimally, allowing you to benefit from reliable conveyor technology.

DRUM COATING

QUALITY PAYS OFF

Our drum coatings made of rubber, ceramic, and polyurethane provide excellent wear protection and improve the frictional connection and corrosion protection of your drum technology, especially for drive drums exposed to strong mechanical forces.

However, our coating services are not limited to drive drums alone. We can also coat deflection drums, bend drums, and idler rollers to permanently enhance their functionality. A crowned rubber coating on your drums can also optimize the straight running of the conveyor belt.

We offer coatings with a variety of materials:

Rubber with various profiles

Ceramic (Remaline CK-X)

Polyurethane (hot vulcanization process)

With our high-quality coatings, we ensure that your drum technology is optimally protected and efficient, ensuring the smooth operation of your conveyor systems.

OUR RANGE OF SERVICES

Thanks to long-standing partnerships with renowned manufacturers, we offer a comprehensive range of services that extends from delivery to comprehensive complete service. Our hot presses allow for optimal connection of your conveyor belt with a width of up to 3,000 mm. This enables us to provide you with the highest quality and reliability in conveyor technology.

Contact person

Hans-Jürgen Grade

Authorized Officer Conveyor Belts & Wear Protection

Tel. +49 (0) 4526 9814

E-mail grade@~@mahnke.de

Contact Person

Michael Ehm

Division Management Conveyor Technology & Wear Protection

Tel. +49 (0) 4526 9821

E-mail ehm@~@mahnke.de