Revolutionäre Zuverlässigkeit für Korrosionsschutz. Getestet in Laboren, bewährt in der Praxis. Unsere Werkstoffe aus der REMA TIP TOP – Palette sind Ihre beste Wahl!

Unsere Spezialisten analysieren individuell die Gegebenheiten Ihrer Anlage: Oberfläche, Prozessparameter, Medienzusammensetzung, Konzentrationen, Temperaturen und Risiken.

Vertrauen Sie auf die Expertise der Peter Mahnke GmbH - zertifiziert nach DIN EN ISO 9001:2008 und überwacht vom TÜV Nord gemäß dem Wasserhaushaltsgesetz WHG seit 1997.

Sprechen Sie uns gerne auf die vielfältigen Möglichkeiten an.

Verschleißschutz

Für eine höhere Lebensdauer

Schützen Sie Ihre Anlagenteile vor Verschleiß und vermeiden Sie ungeplante Produktionsausfälle. Beim Transport und der Verarbeitung von Stück- und Schüttgütern entsteht Verschleiß an ungeschützten Komponenten. Besonders der abrasive Verschleiß verkürzt die Lebensdauer erheblich. Setzen Sie auf unsere Lösungen für dauerhafte Anlageneffizienz.

CHEMONIT

Höchste chemikalienbeständigkeit

Entdecken Sie die herausragende Chemikalienresistenz von CHEMONIT Hartgummierungen. Sie bieten erstklassigen Schutz vor Mineralsäuren, Basen, organischen Lösungsmitteln und Wasser. Mit einer Vielzahl von Haftsystemen und flexiblen Vulkanisationsmöglichkeiten passen sie sich perfekt an Ihre Anforderungen an. Unsere Hartgummierungen sind vom DIBt gemäß WHG §19 l zugelassen und eignen sich ideal für die sichere Lagerung von wassergefährdeten Stoffen.

REMACLAVE 60 ISO/803

Zuverlässige Autoklaven-Vulkanisation

REMACLAVE 60 ISO/803 - Das führende Gummierungssystem für den Schiffbau und die Schifffahrt. Speziell entwickelt, um den anspruchsvollen Bedingungen von ölhaltigem und chloriertem Seewasser standzuhalten, ist REMACLAVE 60 ISO/803 die bevorzugte Wahl für seewasserführende Leitungen.

Industriekletterer

Nach Fisat

Sparen Sie Kosten bei der Gummierungsprüfung! Unsere speziell ausgebildeten Industriekletterer nach FISAT sind gleichzeitig erfahrene Vulkaniseure. Sie ermöglichen eine gründliche Prüfung Ihrer Anlage, ohne auf teure Gerüste angewiesen zu sein. Selbst Reparaturarbeiten können in den meisten Fällen direkt am Seil durchgeführt werden, was eine vollständige Einrüstung überflüssig macht.

CHEMOLINE

Widerstandsfähige Weichgummierungen für chemische Beständigkeit und hohe Abriebfestigkeit.

Beständige Weichgummierungen für Chemikalien und Abriebfestigkeit. Vulkanisierungsoptionen und DIBt-Zulassungen für sichere Lagerung wassergefährdeter Stoffe. Vertrauen Sie auf CHEMOLINE für langlebige und chemikalienbeständige Lösungen.

COROFLAKE

SPACHTELBESCHICHTUNGEN

Unsere Spachtelbeschichtungen auf Basis von Polyester- und Vinylesterharzen, verstärkt mit mikrodünnen C-Glasplättchen, bieten herausragende Leistung und Vielseitigkeit. Diese COROFLAKE-Spachtelbeschichtungen können nahezu für alle Medien eingesetzt werden und halten einer Nassbelastung von bis zu 90°C stand. Verlassen Sie sich auf die Qualität und Beständigkeit unserer COROFLAKE-Spachtelbeschichtungen für erstklassige Oberflächentechnik.

Stahlwasserbau

SPRITZBESCHICHTUNGEN

Durch die Aufspritz- oder Aufrolltechnik werden die Vorteile von Spachtelbeschichtungen mit der Anwenderfreundlichkeit von Spritzanstrichen vereint.

Diese Systeme basieren auf hochwertigen Vinylester-, Epoxid- und Epoxid-Novolac-Harzen und sind verstärkt mit C-Glasflakes, Glimmer oder Graphit. Die COROFLAKE-Spritzbeschichtungen bieten einen langfristigen und wirtschaftlichen Schutz für Ihre Anlagen mit einer beeindruckenden Lebensdauer. Sie können bei trockener Belastung Temperaturen von bis zu 230°C standhalten.

Hochwertige glasgewebeverstärkte Beschichtungen - Korrosionsbeständigkeit und Schlagzähigkeit

Unsere glasgewebeverstärkten Beschichtungen mit einer Dicke von ca. 3 mm setzen auf Polyester-, Vinylester-, Epoxid- und Epoxid-Novolac-Harze. Diese Beschichtungen zeichnen sich durch ihre außergewöhnliche Korrosionsbeständigkeit, hervorragende Schlagzähigkeit und hohe Abriebfestigkeit aus. Sie sind optimal geeignet für Anwendungen mit Nassbelastung bei Temperaturen von bis zu 70°C.

TOPLINE

BESTMÖGLICHE BESTÄNDIGKEIT

Unter Verwendung der gleichen Harze wie bei der TOPLINE Serie wird auf Grund des hohen Harzanteiles die bestmögliche Chemikalienbeständigkeit erzielt. Risse im Beton bis zu einer Breite von 0,2 mm können überbrückt werden. Durch den Einsatz der Glasmatten und des flexiblen Harzes

widersteht diese Beschichtung Einsatztemperaturen von 80°C und kann mit Dampfstrahlgeräten gereinigt werden.

COROPUR Polyurethanbeschichtungen für den atmosphärischen Korrosionsschutz.

Effektiver Schutz für Stahlbauteile: COROPUR bietet die perfekte Kombination aus hoher Oberflächenhärte und hoher Elastizität. Diese einkomponentigen Beschichtungssysteme lassen sich einfach im Streich-, Roll- und Spritzverfahren auftragen und zeichnen sich durch ihre hohe Feuchtigkeitstoleranz aus.

STAHLTEILE

DER PERFEKTE SCHUTZ

Korrosionsschutz nach DIN EN ISO 12944-5: COROPUR für Stahlteile.

Vertrauen Sie auf COROPUR Ferro, COROPUR Ferro LS und COROPUR Cover RAL in Kombination mit passenden Grundierungen. Effektiver Schutz garantiert.

STAHLWASSERBAU

KORROSIONSBESTÄNDIGKEIT

Korrosionsschutz im Stahlwasserbau: COROPUR für zuverlässigen Schutz.

Setzen Sie auf COROPUR Tar, COROPUR Tar21, COROPUR TF21 und COROPUR Non Abrasiv in Verbindung mit geeigneten Grundierungen. Effektiver Korrosionsschutz nach DIN EN ISO 12944-5.

FLEXTHANE Polyurea-Beschichtungen: Vielseitiger Oberflächenschutz.

Hochreaktives 2K-Spritzsystem auf Polyureabasis. Geeignet für Stahl, Beton, Kunststoffe u.v.m. Unempfindlich gegen Feuchtigkeit, niedrige Temperaturen und Umgebungsbedingungen. Härte von ca. 95 Shore A. Schutz vor Korrosion, Anbackung und Verschleiß. Anpassbare Schichtdicken von 1,5 mm bis 25 mm+.

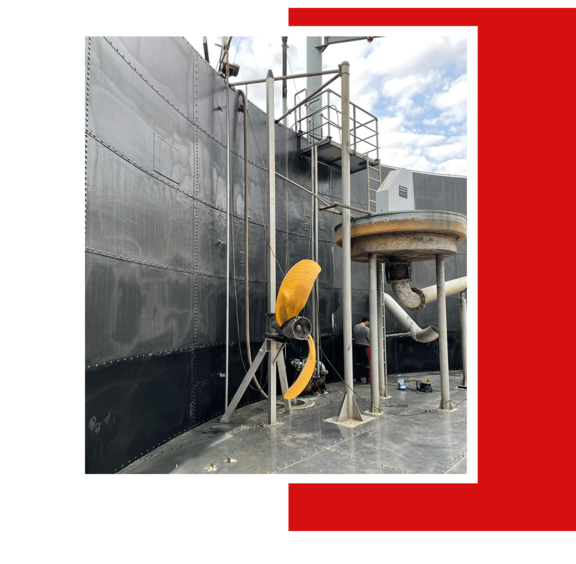

Referenzen

Partner und Kunden, die uns vertrauen

Wir sind stolz auf die vertrauensvolle Zusammenarbeit mit unseren Kunden und Partnern.

ANSPRECHPARTNER

Herr Martin Ahrens

Bereichsleitung Korrosionsschutz

Tel. +49 (0) 4526 9829

E-Mail ahrens@~@mahnke.de